PROFIBUS Manual

Planning a PROFIBUS system takes place with a planning tool. This tool is generally made available by the controller manufacturer and is often closely coupled with programming the controller.

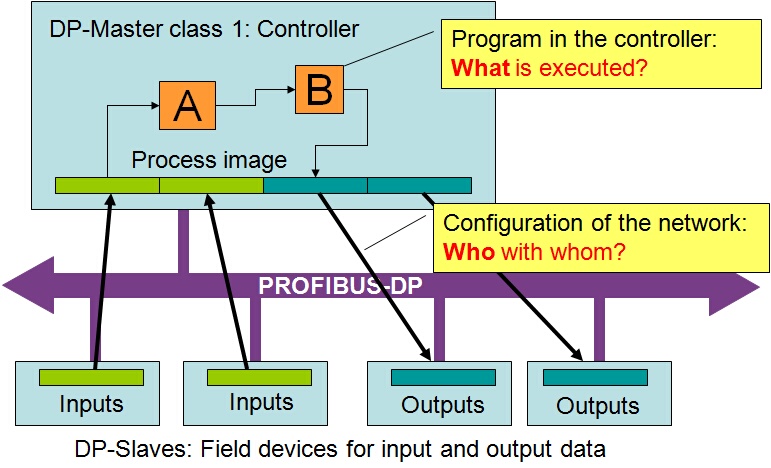

Difference between configuration and programming

Often, however, it is possible to differentiate clearly between controller program task and system configuration. Configuration teaches individual stations who should communicate and exchange data with whom. Programming defines what the controller does with this information. Parameter setting lays down the behaviour of field devices.

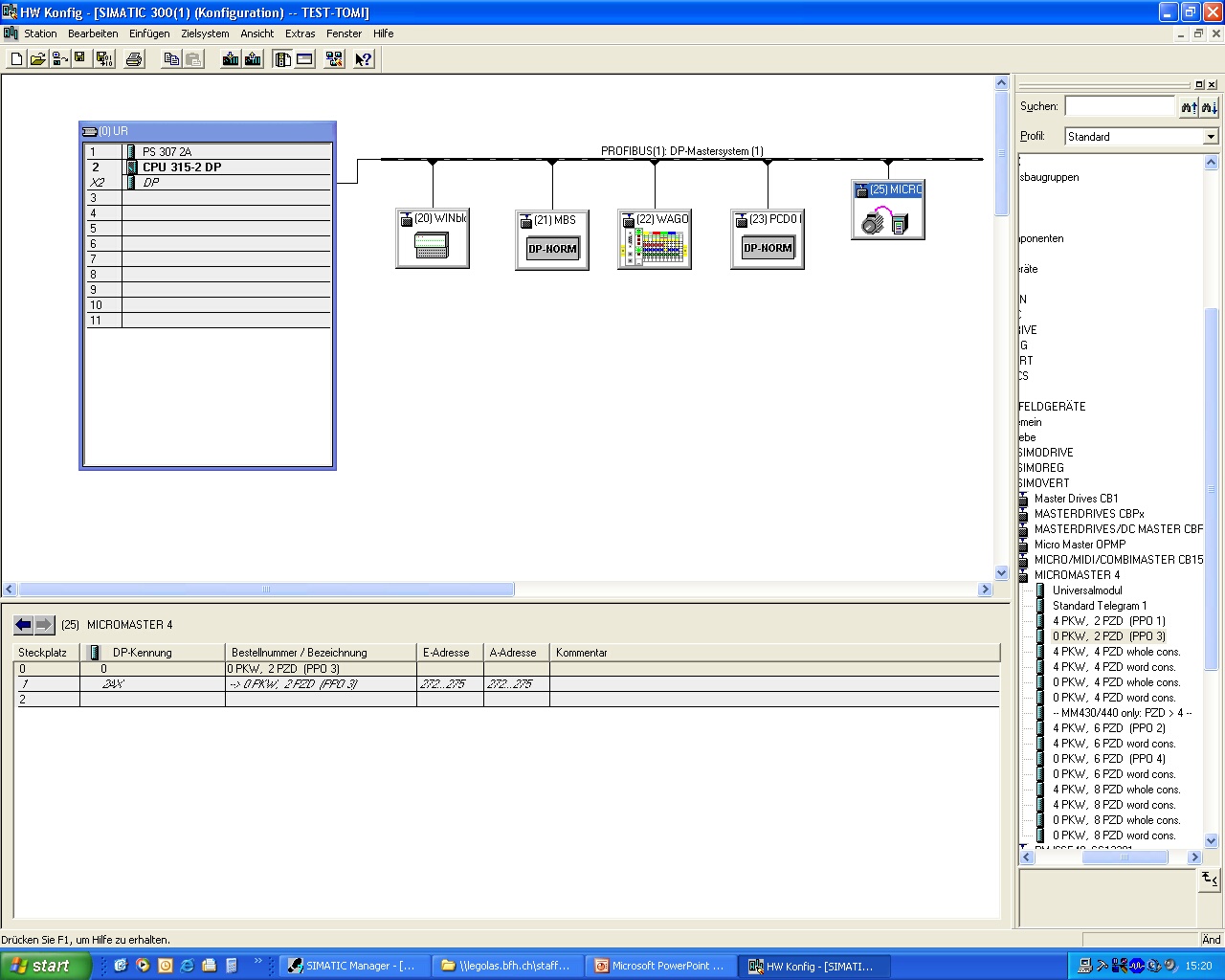

Step 2.1 Plan system

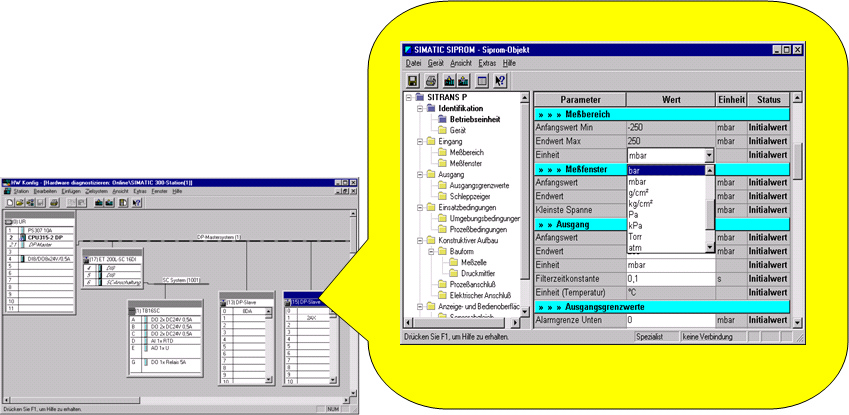

System planning involves assigning field devices to the controller, i.e. the controller is configured. These days this is generally displayed with a graphical interface.

Configuration of a controller

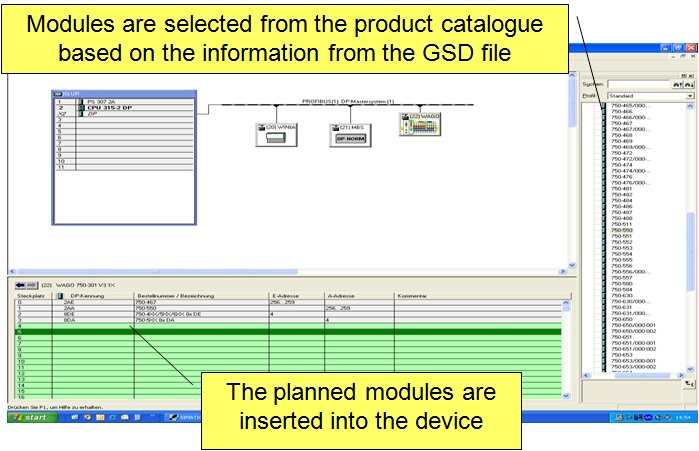

Step 2.2 Configure devices

Configuration of DP slaves (field devices) involves defining the number and type of modules. These modules also determine the number and sequence of cyclic process data transferred from controller to field device and vice versa.

Configuration of a field device

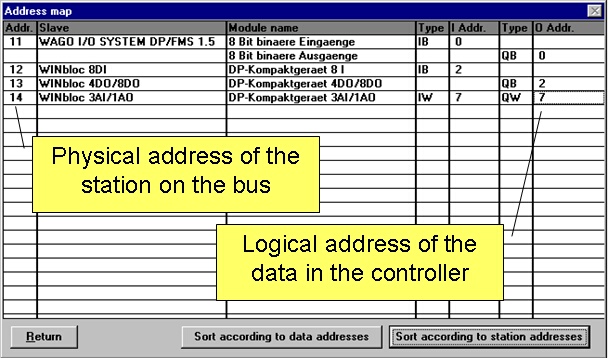

During configuration the controller's logic addresses are assigned to PROFIBUS physical addresses.

Assignment of the addresses

Step 2.3 Set parameters

Parameters are set for controllers and field devices. The individual parameters define how certain functions should be executed within the devices.

Setting the parameters for a field device