PROFIBUS Manual

Diagnostic repeaters take note of an individual segment's connected topology and can, by measuring reflections, identify faults.

Diagnostic repeaters must be planned as DP slaves within the project, so that they are given their own PROFIBUS address. The status of individual segments can be conveyed to the controller through normal device diagnosis.

|

Siemens |

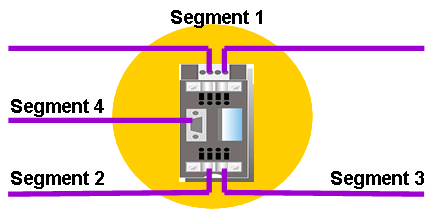

Faults can be detected in segments 2 and 3. The diagnostic connector forms its own segment 4.

The following faults can be detected:

•Line break

•Short-circuit A, B, or against shield

•Bus terminations absent or incorrect

•Sporadic faults during transmission

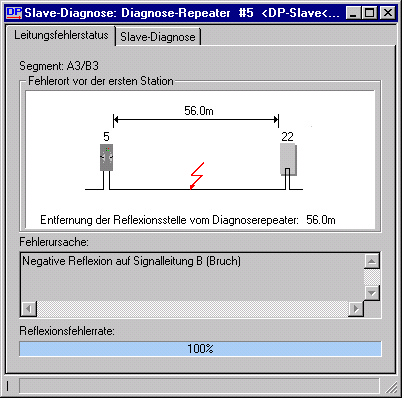

The diagnostic telegram includes the following information:

•Name of segment

•Reason for fault

•Location of fault (including distance in metres)

•Error rate as a percentage

Special diagnostic software (integral to STEP7) allows diagnostic information from the diagnostic repeater to be displayed graphically.

Software for the diagnostic repeater